Structured Cabling’s Top Ten Tips

Structured cabling that is properly installed can help your business grow by helping to improve its network performance and IT capability. The following will discuss structured cabling’s Top Ten Tips for installing cabling systems.

Structured cabling that is properly installed can help your business grow by helping to improve its network performance and IT capability. The following will discuss structured cabling’s Top Ten Tips for installing cabling systems.

#1 Cable Labeling

Although cable labeling will slow installation, it will help save lots of time and effort during future repair, reconfiguration, and maintenance tasks.

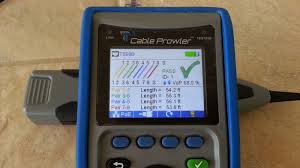

#2 Cable Testing

Ensure every cable is tested and confirmed to be functioning properly during the installation process. A cable with a nominal performance should not be utilized as it may decrease overall system performance.

#3 Short Patch Cables

Do not use long patch cables when they aren’t required. They are inefficient, look disorganized, and are prone to tangling.

#4 Select Quality Terminations

Avoid purchasing cheap terminating cables because time will be unnecessarily spent on troubleshooting in the future. Select those that are of high quality and terminate properly and rapidly.

#5 Avoid Overheating

Keep in mind that maintaining proper cable temperatures to avoid overheating is crucial for stable and reliable network performance.

#6 Measure 2X, Cut 1X

Precise measurements prior to cutting will minimize damaged and wasted cables during installations.

#7 No Kinky Fiber Cables

As fiber cables have great flexibility, they can kink bend, and knot. These will result in flaws in the fiber cables, negatively affecting performance of the network.

#8 Maximum Cable Length

Do not exceed the maximum length of a cable run, which is typically 100 meters for network cabling systems.

#9 Allow for Expansion

Network cabling systems should always have room for interior expansion. As a business grows, its network should have the room to be able to upgrade or expand.

#10 Qualified Installation Company

In order to ensure that a company’s network cabling system will be properly installed, management must select a qualified installation company and request references. Their technicians should be BICSI certified and experts in ANSI standards.

Progressive Office Cabling

Founded in 1986, Progressive Office’s success has been a direct result of years of commitment to seeking solutions on behalf of our clients in the Washington, D.C. and New York City areas. Efficiently working together, Progressive teams get cabling installed and operating as fast as possible while minimizing disruption and downtime. Call our toll free number (800) 614-4560 today.

Testing always plays a vital role in the process of installing new

Testing always plays a vital role in the process of installing new

The conventional process of

The conventional process of